MDG 15 (Guideline for Mobile and Transportable Equipment for Use in Mines) sets out the safety requirements for the design, manufacture and. operation of Mobile and Transportable Equipment for Use in Mines. MDG15 was first published in 1992, and revised in 1994, 1997 and 2002.

Marking, labelling and signs are important as they identify the plant and assist in the safe use of plant over life cycle activities.

Markings, Signs & Labels

Where appropriate, permanent markings, signs and labels should be in accordance with AS 1318, AS 1319, ISO 3864, ISO 7010 and ISO 9244. Where a hazard could exist from the misinterpretation of a symbol the meaning of the symbol should be clarified in writing.

Construction and Location of Markings, Signs & Labels

Markings, signs and labels should be of durable construction, be permanently attached and be appropriate for the environment. Markings, signs and labels should be installed or positioned and maintained so that they are clearly visible.

Labelling

As a minimum, labelling should include:

a) identification of all controls including direction of movement where applicable in accordance with ISO 6405-1 and ISO 6405-2

b) isolation points

c) emergency egress points

d) emergency stops with "EMERGENCY STOP" written.

e) emergency engine shutdown

f) Information is also available in ISO 7010-E020

Compliance plates

Compliance plates or conformance marks should be provided on components where required by the relevant standard and should be displayed in a prominent position. For example, ROPS, FOPS, pressure vessels.

Mobile plant name plates

Mobile plant should have a name plate which provides the following information. a) the manufacturer and plant model b) the year of manufacture and the mobile plant serial number c) weight related limits of the plant, such as tare weight, gross weight, ROPS weight d) other appropriate plant details.

Limits of application In the operator’s cabin, information should be provided regarding all limits of application of the plant. On board identification of grade (cross and fore/aft) with the safe limits identified should be provided. This applies particularly to rubber tyred plant, track mounted plant and overburden drills but should also be considered for other plant. Plant operators are often not able to estimate the grade they are operating on, particularly less experienced operators. Operator error in estimating grade has been identified during accident investigations for drill rigs, excavators, loaders, articulated trucks and cranes. Note: This information assists in correct operation of mobile plant, it should not be considered a substitute for task risk assessment, operator training and the use of fit-for-purpose plant.

Warning and danger signs

As a minimum warning signs should include:

a) a warning sign adjacent to all accessible rotating components

b) a warning at all accumulators that pressure is to be safely released or isolated before work commences. Refer to MDG 41.

c) a warning on any spring applied component that it contains a spring under compression

d) a warning that "hearing protection should be worn” is to be placed on the plant at relevant locations where the noise exceeds regulatory levels and personnel are required to carry out operational or maintenance activities. For further information: ISO 7010-M003, ISO 7010-W038 and the for Managing noise and preventing hearing loss at work code of practice

e) a warning that the park brake should be applied and implements lowered before leaving the mobile plant

f) any other relevant danger or warning signs as identified by risk assessment

g) for analogue gauges, minimum safe operating limits should be indicated by green and red zones. For digital displays, a clear visual or audible indication should indicate whether the pressure is outside the safe operating range

h) any automatic or self-starting plant or plant started remotely should be identified as such. Further guidance may be typically found in ISO 7010-M003 and ISO 7010-W038.

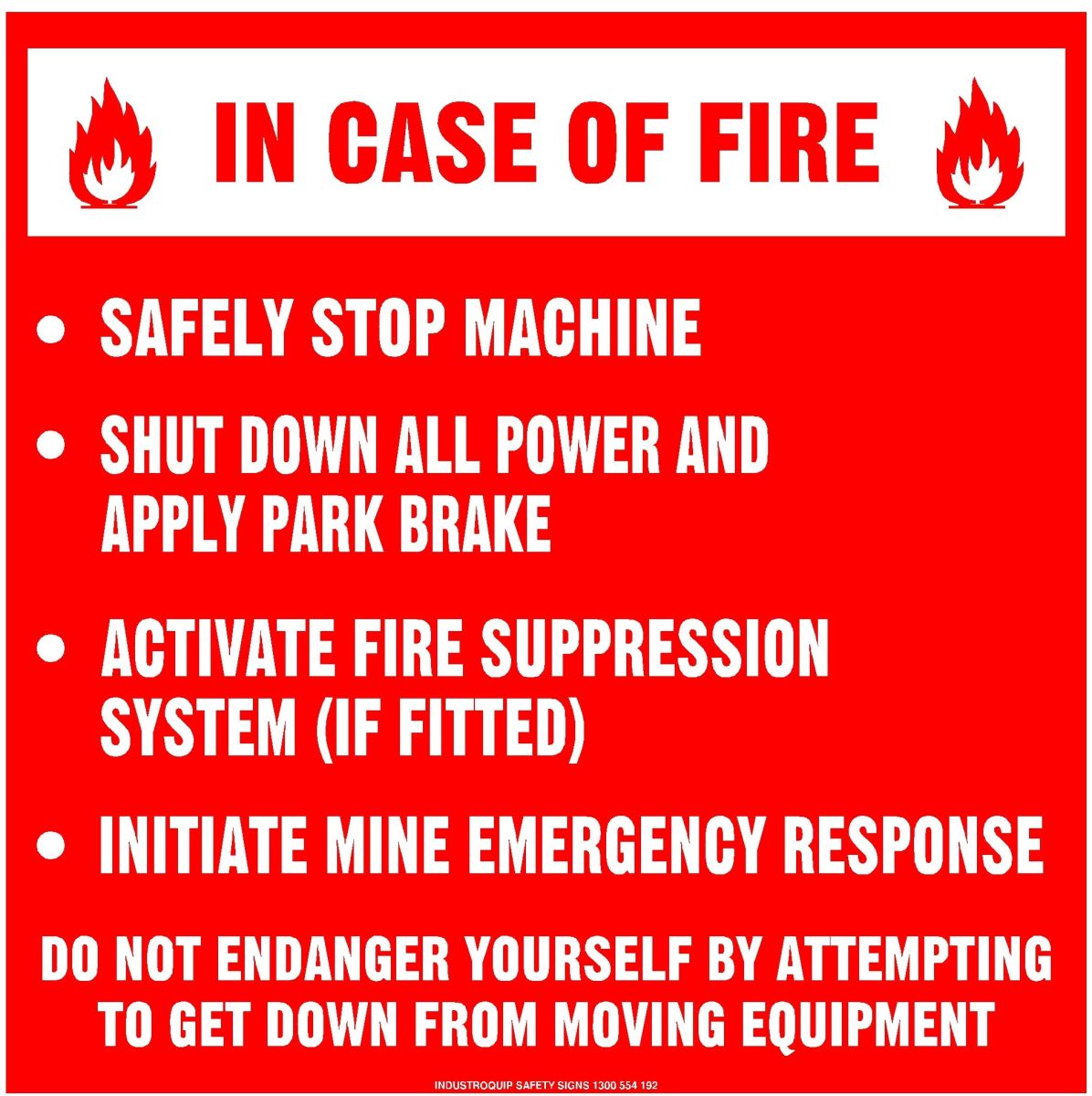

Action in event of fire

The required operator action in event of a fire occurring should be provided within the operator compartment visible from the normal operating position, similar to the following:

Towing, lifting, jacking and supporting plant

Information on the designated locations for towing points, lifting, jacking, tie-down and supporting the plant should be identified in the manual including appropriate instructions. All towing, lifting, jacking, tie-down and supporting points on plant should be appropriately identified. For example, labelled and painted a different colour for identification.

Industroquip make Safety Labels, Markings & Signs to MDG15 specifications every day, if there is anything we can assist with please let us know on 1300 554 192 or visit the NSW Resources Regulator MDG 15 guidelines by clicking this link now:

We trust you found this learning hub post helpful.

Leave a Comment